ukuguqulwa kokuphotha okuhlangene

Umgomo wokuphotha okuhlangene

Inhloso yokuphotha okuhlangene ukuhlela imicu endaweni ehambisana ngokuphelele futhi esondelene ngaleyo ndlela kususe unxantathu ojikelezayo. Ngakho-ke lokhu kulungiselelwa okusondelene nokuhambisanayo kwemicu ngaphambi kokusonteka kungathuthukisa ukwakheka kwentambo, izakhiwo zemishini nezomzimba namandla entambo. Ngamafuphi, ukuphotha okuhlangene kuwukuhlanganisa imicu yentambo ukusuka endaweni yokuphuma phambili yerola eliphezulu.

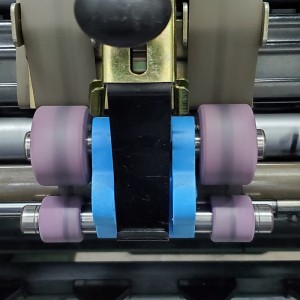

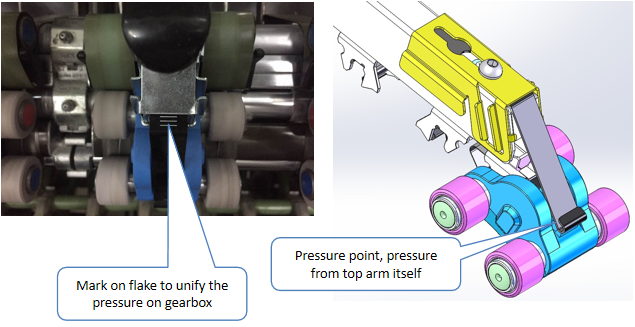

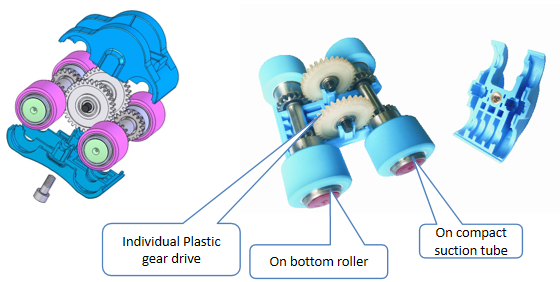

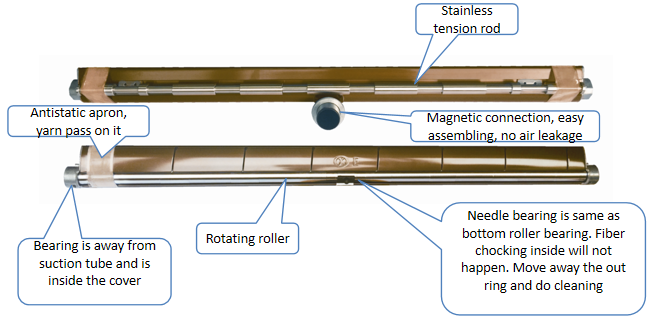

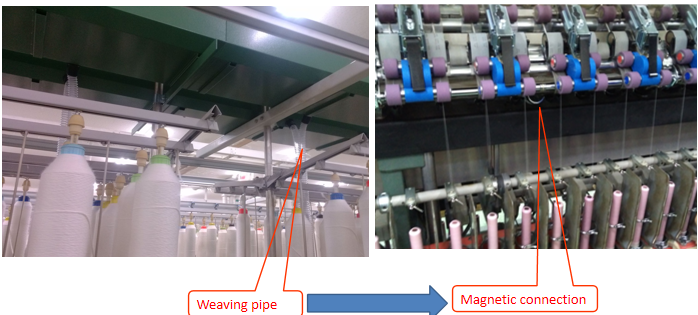

Idivaysi yethu ehlangene iwukwenza amafiber asondelene ukusuka endaweni yentambo ye-nip (i-rola engaphezulu yangaphambili) iye ekugcineni okusontekile ngokumisa idivayisi efana neshubhu yokucindezela okunegethivu, iphinifa elinezikhala kanye nebhokisi legiya, elingaqeda unxantathu ojikelezayo.

Umgomo wokuphotha okuhlangene

* Izinwele ezinciphe ngendlela emangalisayo: Inani le-Uster H lifika ku-30% Zweigle S3 lifika ku-80%

* Amandla athuthuke kakhulu: 10-20% ngaphezulu

* Ukungalingani kwentambo ephansi kanye namanani aphansi e-IPI: kufika ku-35%

* Ubude obuphakeme: ngo-10 kuye ku-15%

* Nge-twist ephansi (kufika ku-10%) ukukhiqiza amandla entambo efanayo kuyakhuphuka

* Izinga lokuqhekeka kokuphela kwehliswe kufika ku-60% ukuthuthukisa ukusebenza kahle komshini (isivinini esifanayo nokusonta)

* Ukukhiqiza izimpukane ezincane kusiza esimweni esingcono sokusebenza

Ukwenyuka kwezivinini zokumazongo

* Intambo eyodwa ehlangene ingangena esikhundleni sentambo evamile enamaply amabili

* Ukusebenza komshini wokumpintsha nokuluka kukhuphuke ngo-10-15% ngenxa yamandla aphezulu;

* Ukusetshenziswa kwamakhemikhali okulinganisa kuncipha ngenxa yezinombolo ezincane zemicu ephumayo;

* Ukuncipha kokusebenza kahle kwezinwele kukhuphuka kanye nokuncipha kokukhiqizwa kwezimpukane;

* Emikhiqizweni eqediwe, ukuthambekela kokuphuza okuncane, ukuthinta okungcono, ukucwebezela kwendwangu

* Ukumuncwa kotshwala bedayi kwenziwe ngcono ngenxa yokusonteka kwentambo ephansi, uphuzo oludayi oluncane oludingekayo (kufika ku-5%)

* Ukonga impahla eluhlaza - umsindo we-comber omncane ofika ku-6%

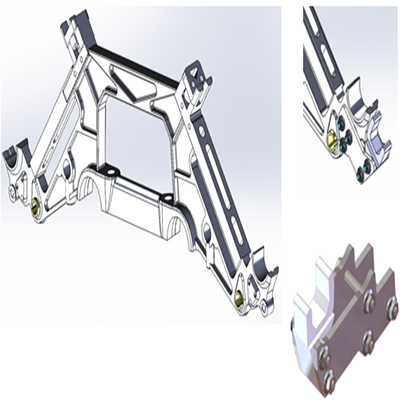

I-Compact Drafting System ku-Pneumatic top arm

Ishejuli yesondlo sikakotini onamakhadi wama-20s:

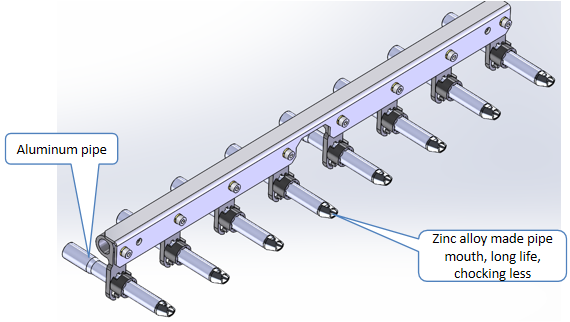

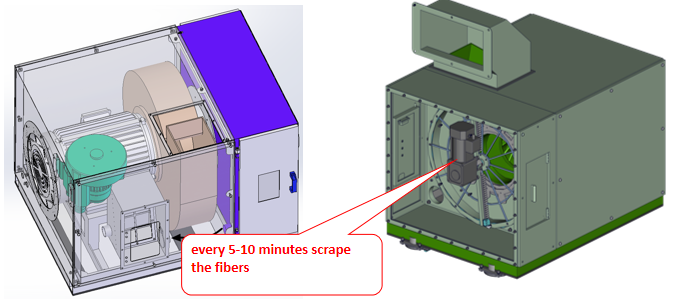

1. Ukuhlola nsuku zonke noma yimuphi umonakalo wemibhede, ukuchotshozwa komtshingo we-pneumafil, ukucindezela okungalungile kwe-tube slot chocking;

2. Kanye ezinsukwini ezingu-7-10 ukuhlanza ithubhu yokucindezela okubi;

3. Ukubhucungwa kwezingubo zombhede kufanele kwenziwe kanye ezinsukwini ezingama-45 (kuye ngekhwalithi yentambo) futhi isilinganiso esifanayo sokungezwani kufanele sigcinwe;

4. Kanye ezinsukwini ezingu-30 ukuhlanza umshini ogcwele kufanele kwenziwe;

5. Ngesikhathi sokuhlanza umshini ngokugcwele ikhava yokuphela kwepayipi kufanele ivuleke futhi injini ehlangene kufanele iqhutshwe mathupha ukuze kuhlanzwe ipayipi;

6. Uma kwenzeka ukugqwala pls clean ngesikhathi

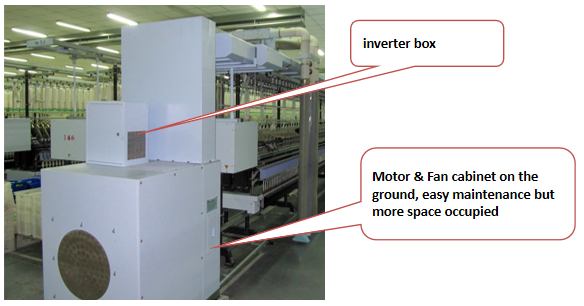

Ukusetshenziswa kwamandla

| 1824 ama-spindles/ Umshini | amandla emoto | I-ABB inverter | ukusetshenziswa kwamandla/okuphotha | I-negative tube slot value |

| Ihlangene yochungechunge olulodwa | 22kw/60Hertz

| 22kw | 7-8w | 2.5-2.8Kpa |

| Ihlangene yentambo ye-siro | 22kw/60Hertz | 22kw | 8-9w | 1.6-1.8Kpa |